MicroAge experiment delivered!

The scientific hardware designed and manufactured by Kayser Space has reached the International Space Station on board SpaceX-24 in December 2021.

The project, funded by the UK Space Agency and led by Prof. Malcom Jackson of the University of Liverpool, was kicked off three years ago. After the design the manufacturing and the rigorous testing campaign, necessary to certify the hardware for its use on a manned space mission, the programme reached its climax on December 18th, when the scientists of Liverpool and the Kayser Space engineers carried out the final sample preparation and integration at the Space Station Processing Facility at the NASA Kennedy Space Center in Florida.

The samples are muscle fibres and have a limited life. So, they have to be prepared few hours before launch and for this reason the team members had to gather and work hard to deliver the hardware as late as possible. The NASA specialists had the critical task to load the hardware in the spacecraft already prepared at the launch complex 39A.

The spacecraft liftoff was nominal at 5:06 ET (10:07 GMT) on December 21st. The Dragon capsule docked at 08:41 GMT on December 22nd, the samples were transferred to the ISS and then integrated in the Kubik incubator of the Columbus module. This operation was carried out by the ESA astronaut Matthias Maurer on December 23rd at 09:00 GMT. After two days of incubation, the samples were transferred to a freezer on board, ready for return with the same spacecraft at the end of January.

McroAge is the third Kayser Space hardware visiting the ISS in 2021, after Bioasteorid (SpaceX-21) and MME-2 (SpaceX-22). The first was a project privately managed by the University of Edinburgh, while the second was a research conducted by scientists of the University of Nottingham and Exeter and funded by the UK Space Agency.

|

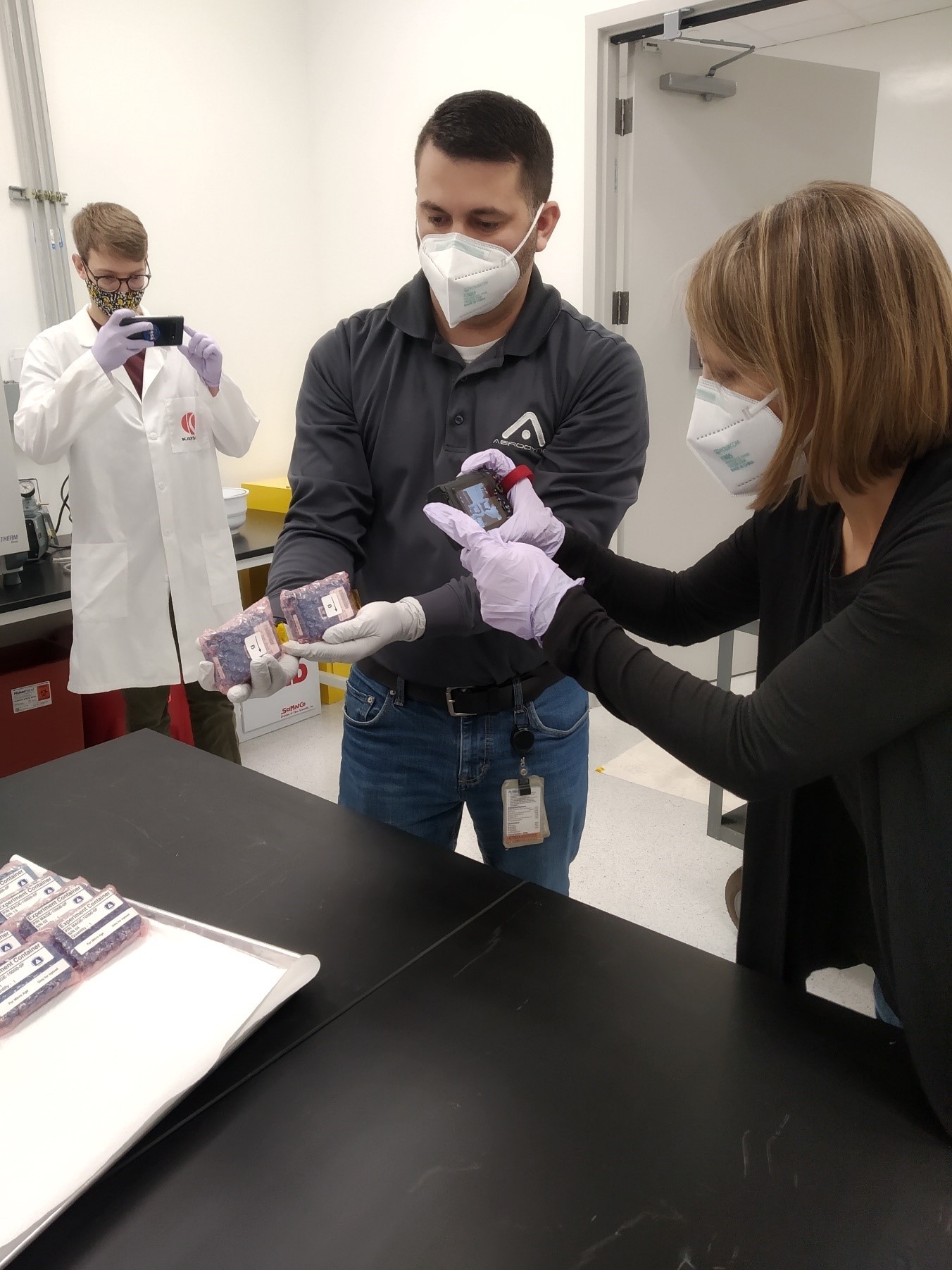

Kayser Space engineers and the scientists of the University of Liverpool with the MicroAge flight units ready for delivery to NASA |

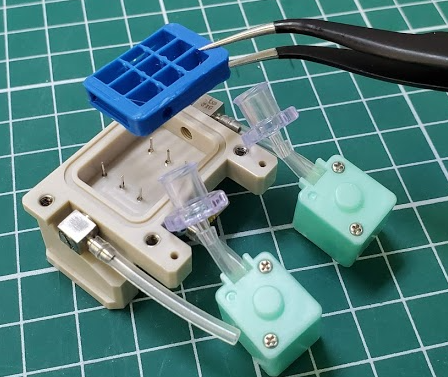

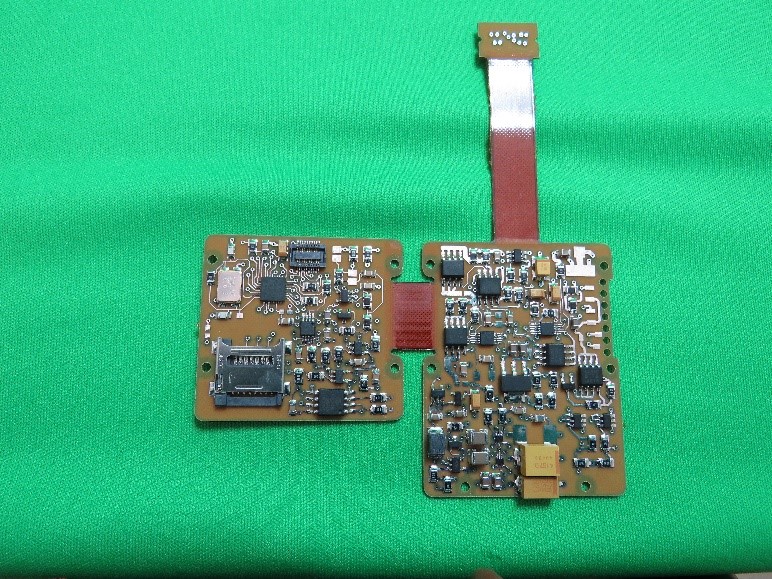

MicroAge scientific hardware under preparation |

|

NASA payload specialists inspecting the MicroAge hardware ready for integration into SpaceX-24 spacecraft |

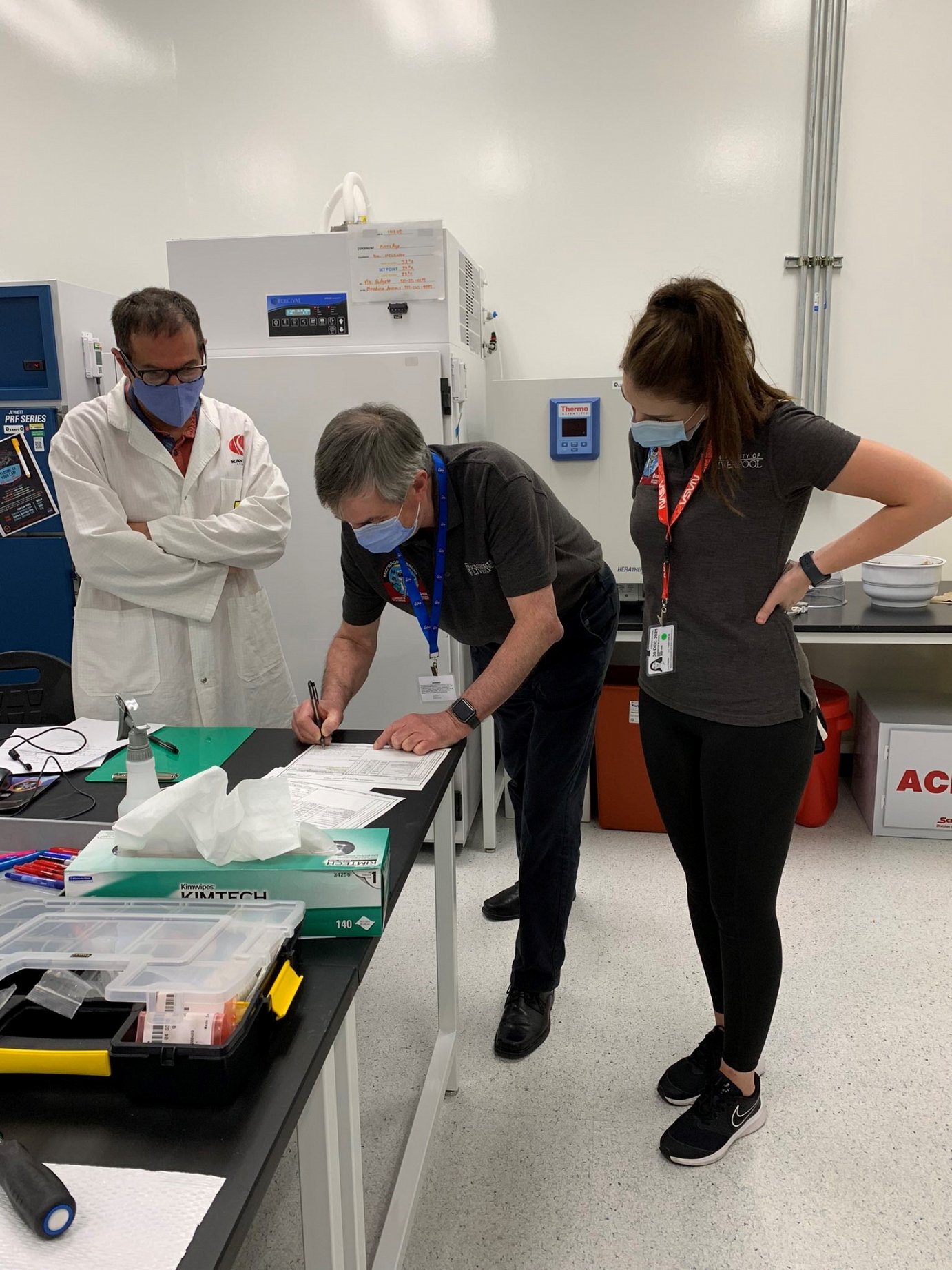

Prof. M. J. Jackson, MicroAge principal investigator and Gianluca Neri, Kayser Space programme lead, signing off certification for sample safety clearance

|

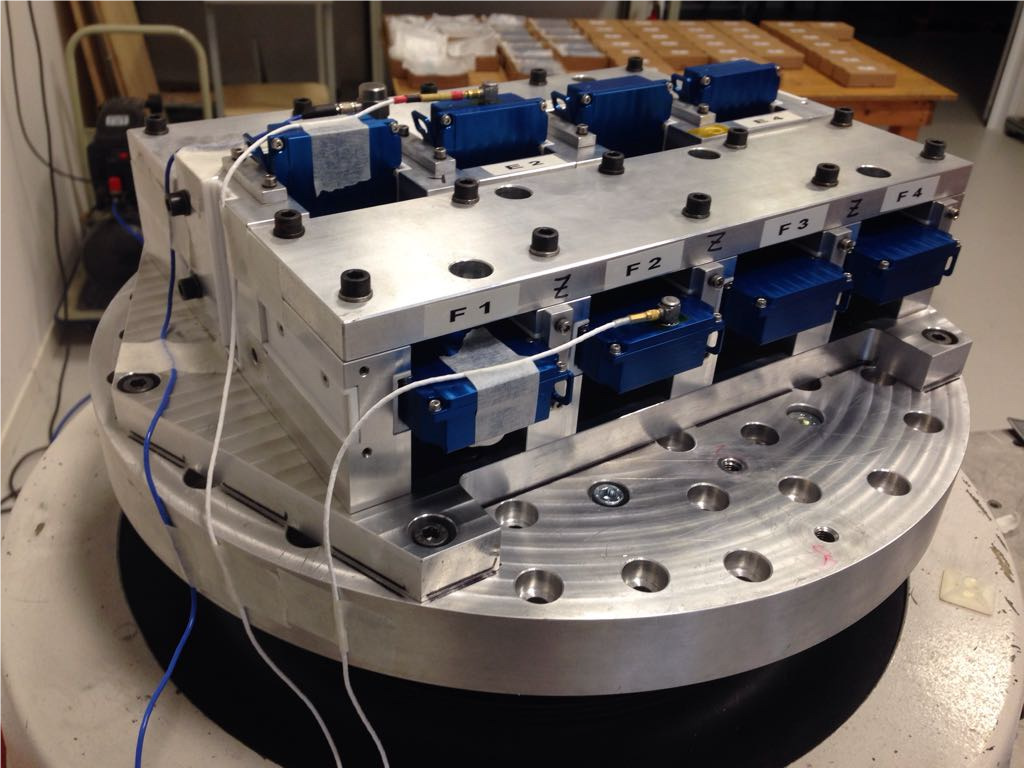

ESA astronaut Matthias Maurer performing the MicroAge hardware integration in KUBIK (Photo credit: ESA/NASA) |

|